Quick Contact

Custom EMI Shielding Solutions for Board level Applications

At XGR Technologies, we specialize in custom EMI shielding solutions tailored for board-level applications. Our innovative SnapShot® board-level shields are custom designed and manufactured to meet your specific design requirements, ensuring unparalleled performance and efficiency.

Using an advanced thermoforming process, XGR Technologies delivers custom EMI shields with rapid turnaround times, providing a competitive edge for our customers. Over the years, we’ve invested in state-of-the-art manufacturing equipment and engineering expertise, allowing us to produce high-quality, reliable custom board-level shielding solutions faster and more flexibly than conventional methods.

Why Choose SnapShot® Custom EMI Shields?

- Unparalleled Design Flexibility:

- Our advanced thermoforming process enables us to create shields in virtually any shape and size, perfectly conforming to your complex board layouts.

- Say goodbye to design limitations and optimize your device's performance and board real estate.

- True Multi-cavity Capability:

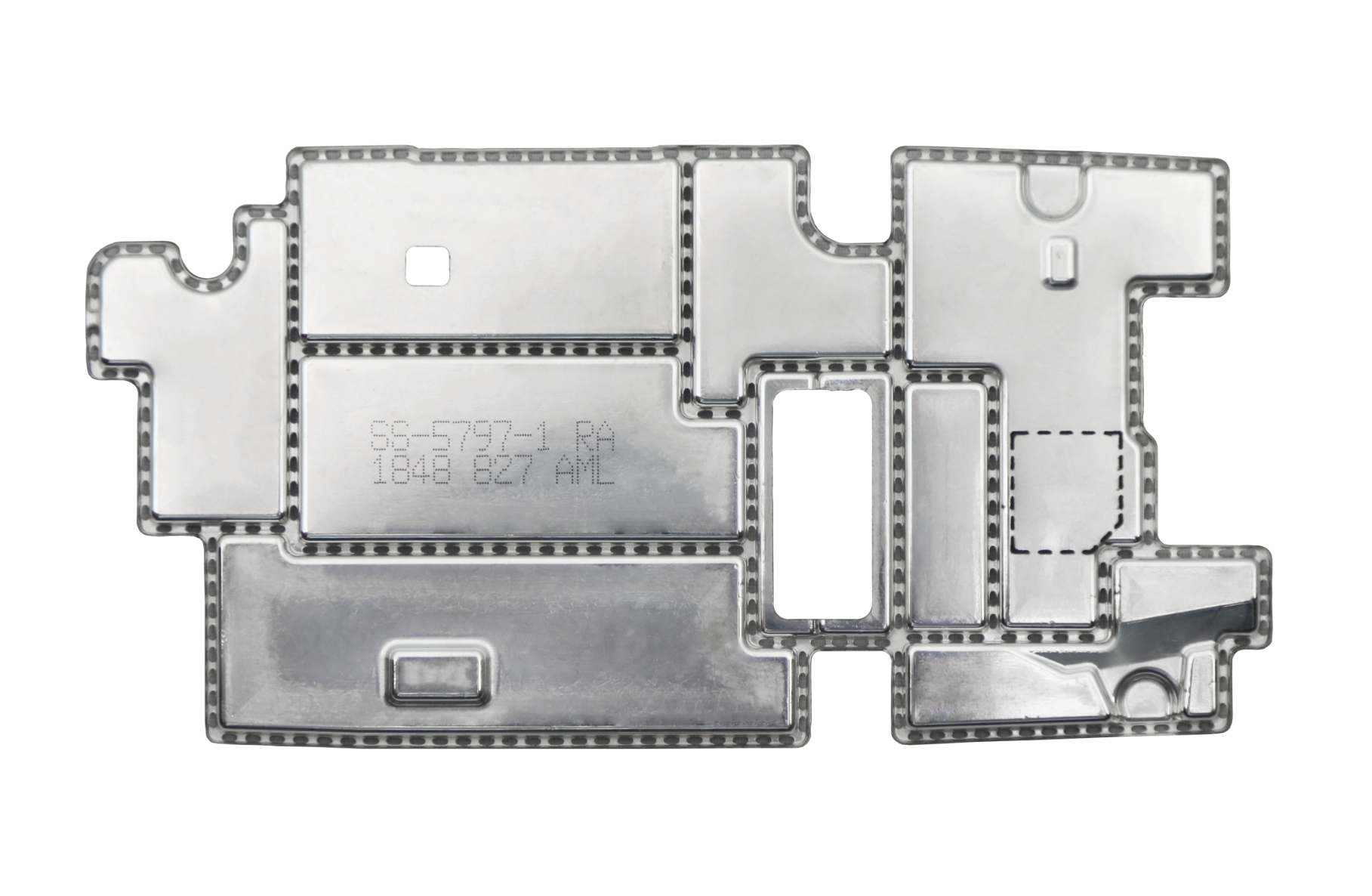

- Our technology enables multi-cavity shields where cavity to cavity isolation is equal to the isolation from the external environment to the internal shielded cavities.

- Lightweight Shielding:

- SnapShot® technology based on a lightweight, engineered polymer resulting in the lightest weight board level shield available.

- Rapid Turnaround Times:

- Our streamlined manufacturing processes and commitment to efficiency ensure fast delivery of your custom shields, minimizing project delays.

- Superior Quality and Reliability:

- We utilize high-quality materials and employ rigorous quality control measures to guarantee the durability and effectiveness of our shielding solutions.

- Expert Engineering Support:

- Our team of experienced engineers collaborates closely with you throughout the entire design and manufacturing process, providing expert guidance and ensuring your complete satisfaction.

How Our Custom EMI Shielding Process Works:

- 3D Modeling and Customization:Our engineers work closely with you to develop a precise 3D model of your custom EMI shield, ensuring compatibility with your design files and eliminating interference in X, Y, and Z dimensions.

- Advanced Manufacturing:Using the 3D model, we produce a machined metal mold to manufacture your shield with pinpoint accuracy, optimizing both functionality and space utilization.

Superior Space Utilization with SnapShot® Custom EMI Shields

Our innovative approach ensures optimal use of board real estate. For instance, we created a round, multi-cavity shield for a GPS consumer watch to maximize board space on a round PCB—a task traditional square or rectangular shields cannot achieve.

Custom EMI Shielding - Applications and Success Stories

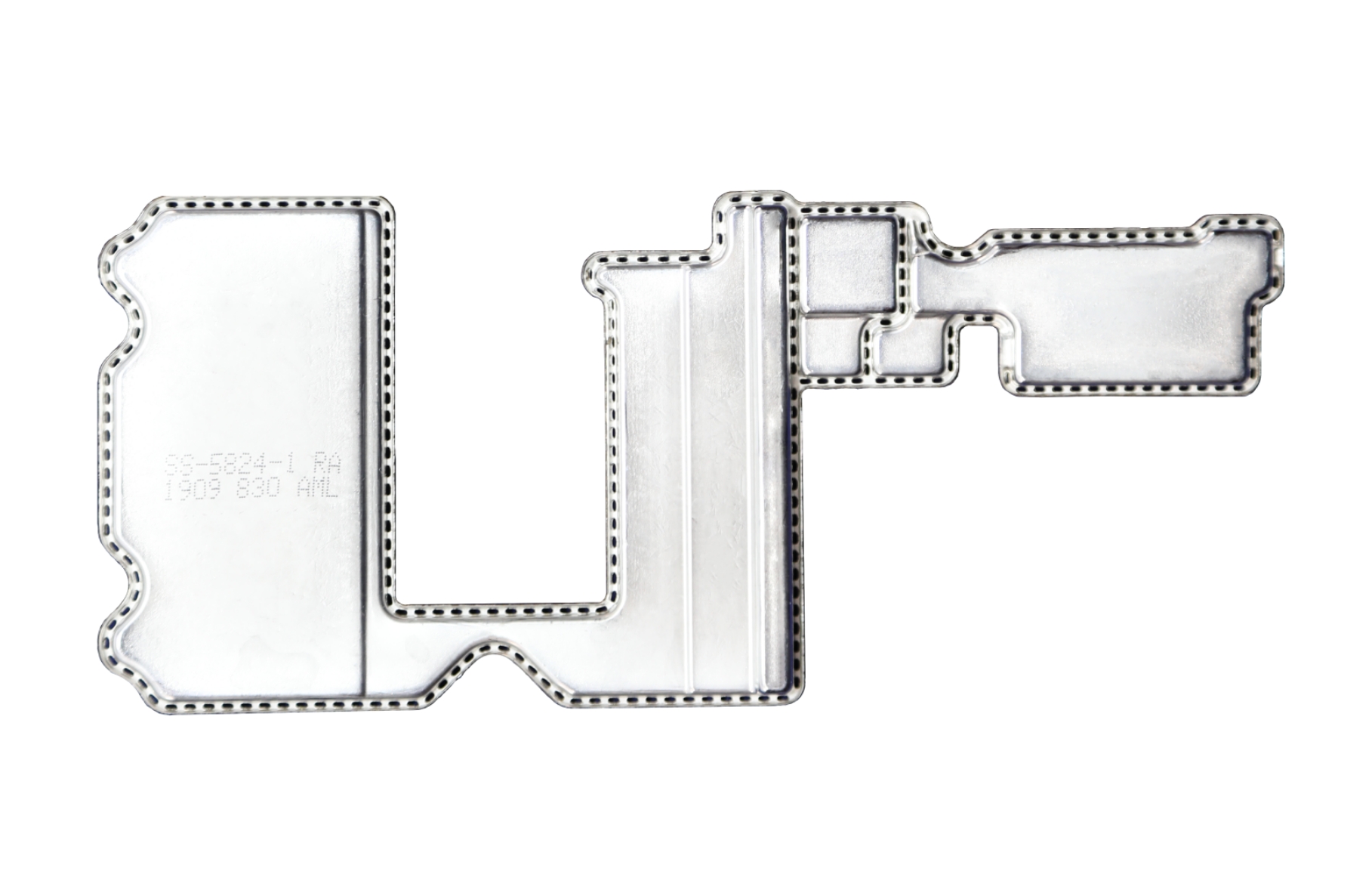

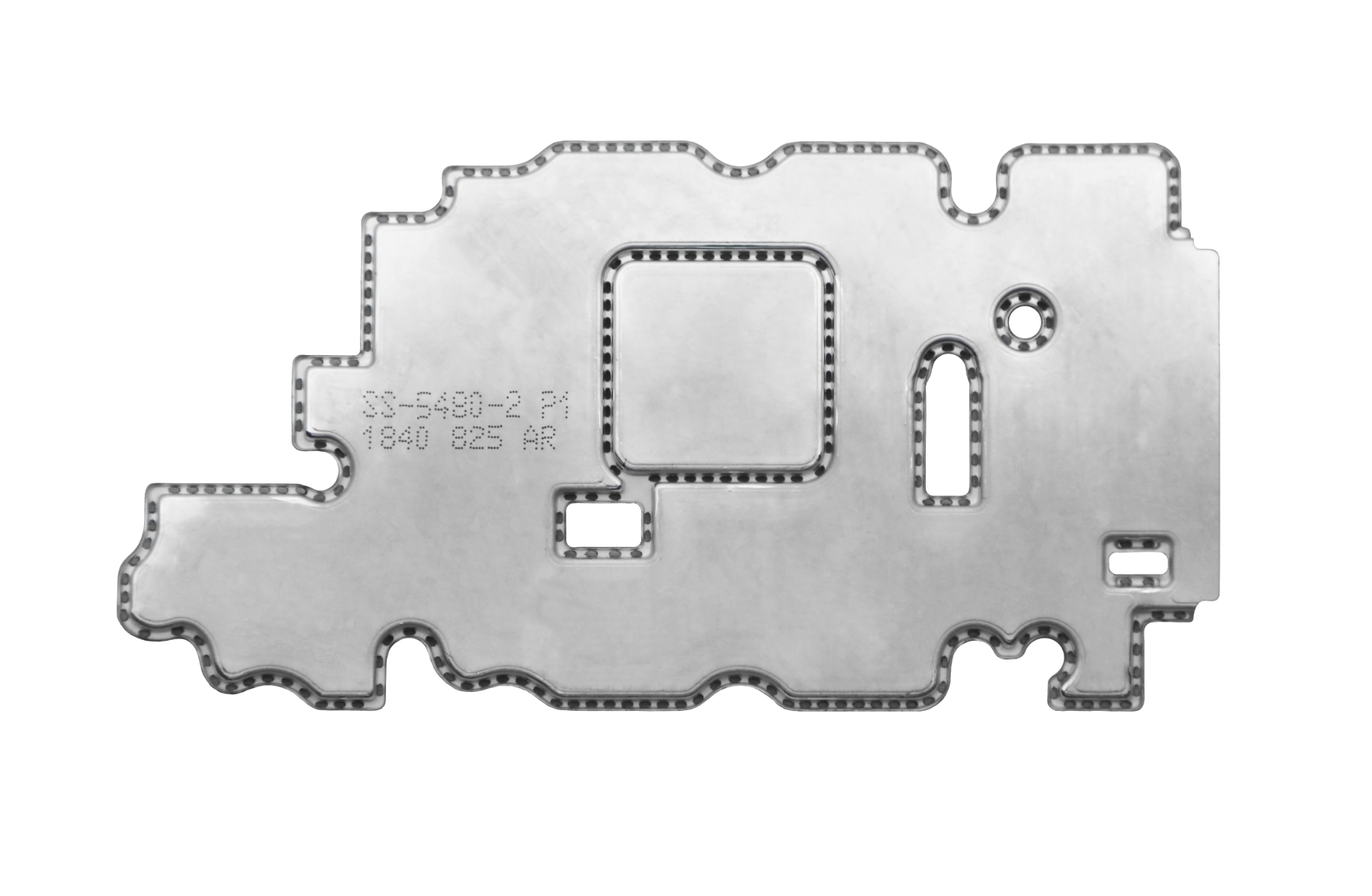

From simple configurations to intricate designs, SnapShot® shields provide high precision, flexibility, and durability Explore our gallery for examples of how customers have leveraged our custom EMI shielding solutions to overcome unique challenges in board-level applications.

Partner With XGR Technologies for Your Custom EMI Shielding Needs

With XGR Technologies, you’re not just getting a shield—you’re getting a partner committed to delivering exceptional custom board-level shielding solutions that meet your exact requirements.

Contact us today to learn more about our custom EMI shielding capabilities and how we can help you achieve superior performance and design efficiency for your applications.