Ensuring the accuracy and consistency of data over its entire lifecycle is critical for making informed decisions, maintaining operational efficiency, and safeguarding sensitive information. But what ensures data integrity at its most fundamental level? Data acquisition cards have a role to play here. However, electromagnetic interference is a common issue in data acquisition cards as they gather and convert signals from analog to digital and vice versa. This EMI can hamper the functioning of these cards, and hence they need to be shielded using EMI shields. This post discusses how board-level shields can be effective in mitigating EMI in data acquisition cards and subsequently the systems they are integrated into.

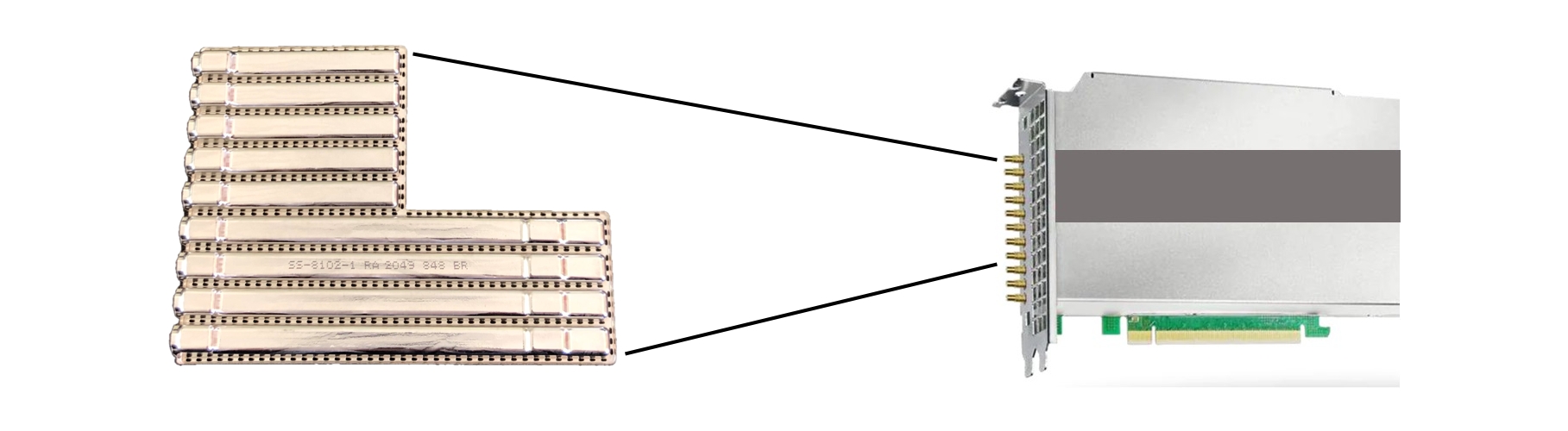

Data Acquisition Card: Shielding edge mount connectors, Multi-Cavity Tx and Rx channels

What Are Data Acquisition Cards?

Data acquisition cards are integral components of computer systems designed to collect and convert analog signals from various sources into digital data for analysis. These cards are pivotal in environments where monitoring and controlling physical processes are essential. They can be found in multiple applications from industrial automation and control systems to environmental monitoring and medical equipment. By accurately capturing real-world signals, data acquisition cards allow for precise measurement, recording, and analysis of physical phenomena, translating into actionable insights and informed decision-making. To continue this normal functioning, board-level shields help a great deal in protecting data acquisition cards from EMI and EFI as well as any possible damage due to environmental parameters. The next section focuses on board-level shields can be used to mitigate EMI in these cards.

Role of Board-Level Shields in Data Acquisition Cards

Board-level shielding is crucial in ensuring the integrity of the data collected by acquisition cards. These enclosures or shields serve as a protective barrier around sensitive components on the circuit board, safeguarding against electromagnetic interference (EMI) and radio frequency interference (RFI). Such interference can corrupt data, leading to inaccurate information and potentially compromising the system's reliability. Here's how board-level shields contribute to securing data integrity in data acquisition cards.

- EMI/RFI Protection: By blocking unwanted electromagnetic and radio frequency signals, board-level shields prevent corruption of the data being processed by the acquisition card. This is particularly important in industrial environments or areas with high levels of electronic noise.

- Enhanced Performance: Shields help maintain the optimal performance of data acquisition cards by ensuring that external interference does not affect the accuracy of signal processing. This leads to reliable data collection and analysis.

- Durability and Longevity: Protecting sensitive components from external elements not only ensures data integrity but also contributes to the durability and longevity of the data acquisition card. This means less downtime and maintenance, translating into cost savings and increased efficiency over time.

- Customization and Flexibility: Board-level shields can be customized to fit specific needs and configurations of data acquisition systems. This flexibility ensures that data integrity can be maintained at the highest standard regardless of the application or environment.

The importance of board-level shields in data acquisition cards in securing data integrity cannot be overstated. As we rely heavily on data-driven decision-making, the need for accurate and reliable data collection systems becomes increasingly critical. By integrating effective shielding solutions, businesses and researchers can protect the integrity of their data, ensuring that the insights derived from this information are accurate and actionable. However, while mitigating EMI, these shields should not block the signals received for conversion or generate too much heat. Hence, it is essential that the shields are lightweight, made of plasticized metal, customized to fit the exact dimensions of the card, and with the right layout in terms of blocking EMI, facilitating isolation as well as ventilation. XGR Technologies, with its expertise in innovative shielding solutions, offers SnapShot® EMI shields that can be customized to fit the exact dimensions of data acquisition cards. Whether you're involved in industrial automation, environmental monitoring, or any field reliant on accurate data collection, understanding and implementing board-level shields in your data acquisition cards is essential for safeguarding the integrity of your data. For further information, feel free to call the XGR team today.